Providing the stamping industry with superior quality tools.

Our team is comitted to providing the stamping industry with the highest quality tools delivered on time .

About Us

Attitude, experience, and technology form a partnership at Proto Cast that has been serving the stamping industry for over forty years. Located in the heart of the motor city, Proto Cast provides a wide range of services for customers across various industries throughout the United States at our 32,000 square foot facility. Advanced Tool Design, Foam Pattern Build, Zinc Alloy (Kirksite) Castings, and complete CNC machining are all provided at Proto Cast.

Our Capabilities

Tool Design

Proto Cast excels in deep draw, wipe/flange, hang-up die, re-strike, CAM action tooling, and reverse engineering.

Foam Pattern

We operate an eco-friendly Zimmerman Foam Machining Center with a large 288″x96″ table size.

Kirksite Foundry

Offering up to 168”x96” flask sizes and 57,000 lbs. daily capacity using hard sand molds and custom coring.

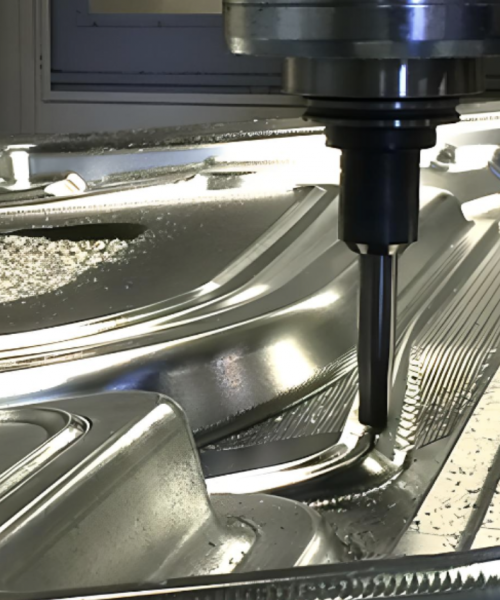

CNC Machining

Proto Cast’s advanced CNC technology, with 10 machines up to 120″x82″, operates 24/7, manned by skilled machinists.

Transportation

Local, Regional and Nationwide delivery and pickup services available for all shipments.

Let's Connect

We invite you to connect with us and experience firsthand the potent blend of attitude, experience, and cutting-edge technology that has been driving our successful journey in the stamping industry.

- Phone313.565.5400

- Fax313.565.5936

Contact Us

"*" indicates required fields